Hotter Heat Pumps could help Electrify Industrial Heat

Most energy in industry is used to provide heat. The most efficient way to decarbonize heat is to use heat pumps powered by green electricity. Which leads to the question: What temperatures can they achieve?

Industrial heat is a major consumer of fossil fuels. Estimates are that around two-thirds of the energy used in industrial applications is used to generate heat.

Industrial heat applications are diverse, and so are the temperatures - from relatively low-temperature use cases like drying food to extremely high temperatures required to melt metals or produce cement.

Electrification of heat will play a major role in the decarbonization of industrial heat. But different needs will require different electric heating technologies.

Heat pumps are a particularly efficient way to generate heat from electricity. They can achieve something that sounds like it violates the laws of physics: They can provide more energy than they consume.

Of course, no technology can violate the laws of thermodynamics. Heat pumps achieve their efficiency by taking energy from a lower temperature source. In the simplest case, this can be outside air. By compressing a heat carrier, they increase the energy per volume and therefore the temperature.

Utilizing this trick, heat pumps can often generate efficiencies of 300% - 500%, depending on the application, sometimes even higher. The efficiency of a heat pump is measured as the Coefficient of Performance (CoP), which is the amount of energy a heat pump provides per input energy. For example, a heat pump providing 4 kilowatt hours of heat energy per one kilowatt hour of electricity would have a CoP of 4 or an efficiency of 400%.

These high efficiencies mean that even in an electricity grid still primarily powered by fossil fuels, heat pumps will usually lead to a decrease in emissions.

Heat pumps for low temperatures below 100 degrees Celsius (~210 °F) are an established technology and are often used in home heating. Industrial heat pumps up to 150 degrees Celsius (~300 °F) are also available, though they are not widely used yet.

Given the huge efficiency advantage, the question is: Can heat pumps provide much higher temperatures? I talked to some people who think so.

Startups and researchers are working on Hotter Heat Pumps

The company Airthium wants to build a heat pump reaching temperatures of more than 500 degree Celsius (~1,000 °F). The startup received funding from Y Combinator, a venture capital firm from Silicon Valley mainly known for funding IT companies. Airthium is registered in the United States, but engineering happens in France.

I talked to Franck Lahaye, one of the founders of Airthium. The company hopes to achieve high temperatures using a compressor with a so-called Stirling engine. Lahaye tells me that they expect high reliability with this design, as it avoids the need for sliding or rotating seals.

Airthium is not the only startup trying this. Olvondotech from Norway also wants to build a high-temperature heat pump with a Sterling engine.

One question is whether this technology can be scaled up. Airthium has a small prototype with one kilowatt, and they are building the next prototype with five kilowatts. But as Lahaye tells me, their potential customers would require between one and five megawatts – a thousand times larger.

In the next step, Airthium wants to break the current record for high-temperature heat pumps. In 2021, the Norwegian research institution SINTEF announced they had achieved 180 degrees Celsius (~350 °F). Airthium hopes to reach 250 degrees Celsius (~480 °F) with its 5 kilowatts model this summer.

But they will not achieve a record if someone else does it sooner. And that could be the team of Uwe Riedel, who leads a heat pump research project in Cottbus, Germany, for the DLR (German Aerospace Center, Deutsches Zentrum für Luft- und Raumfahrt).

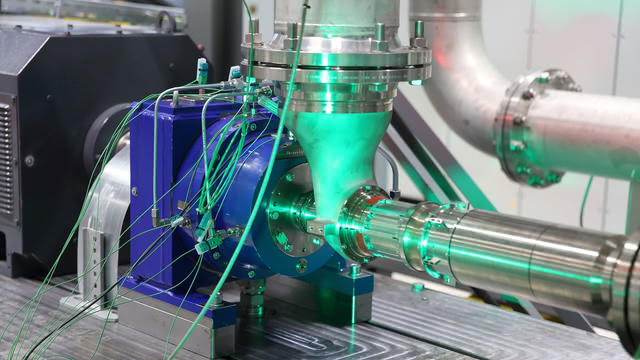

The heat pump the DLR is building is called CoBra, and their current prototype is planned to have a temperature of 300 degrees Celsius (~500 °F) with 250 kilowatts of heat output. The name CoBra stands for Cottbus and Braython cycle - the latter is the name of the thermodynamic process used in this heat pump.

The researchers in Cottbus want to target use cases between 150 and 400 degrees Celsius (~300 - 750 °F). As Uwe Riedel explains to me, they are using compressors and turbines with technology from the aviation industry – something the DLR has a lot of experience with. According to Riedel, they expect that scaling up the technology with this approach will be feasible.

Potential customers could be in the food industry, the paper industry, or rubber processing. "We have analyzed these markets and concluded that our target size will be in the one to ten megawatts range," Riedel said.

I also learned from Riedel that high-temperature heat pumps do not have a problem that is sometimes controversial with more conventional heat pumps: They do not use fluorinated gases.

Fluorinated gases or F-gases are a class of substances that are often used in cooling systems or heat pumps. Many of these gases either damage the ozone layer or are very active greenhouse gases when they leak. Some of these gases are several thousand times more potent greenhouse gases than carbon dioxide.

But high-temperature heat pumps cannot use these gases anyway, as they would not be stable in these high temperatures. Only a few gases are possible candidates for these temperatures, and they all have negligible impacts on the climate, even if they leak.

DLR expects Industrial Installation in three Years

The CoBra team soon wants to produce the first results with their 250 kilowatts prototype and hopes that larger versions will follow. The DLR is currently talking to companies interested in using the technology for their production processes. Riedel tells me their goal is to have the first industrial installation within three years.

The efficiency of heat pumps depends not only on the temperature achieved, but also on the lift. That is the temperature difference between the "cold" heat source and the target temperature. When one wants to go from normal air temperature to very high temperatures, a larger lift is needed, and therefore the efficiency goes down. In industrial settings, using waste heat from other processes is often possible.

Riedel gives me an example: In a setting where a waste heat source with 100 degrees Celsius (~210 °F) is available, and 250 degrees Celsius (~480 °F) is needed, that still offers a CoP value of around two. Not as efficient as the heat pumps used in residential settings, but that still means the heat energy output is twice the electric energy input. Or in other words: Compared to simpler, direct electric heating technologies, this cuts the electricity bill in half.

Once the CoP value gets close to one, using a heat pump no longer makes sense. Much simpler technologies that directly turn electricity into heat are preferable in such a setting. It is unlikely that heat pumps will be used for temperatures much higher than 500 degrees (~930 °F).

But if heat pumps can go up to 500 degrees Celsius, they can provide around half the energy for process heat needed in the industry. That is a lot of heat that could be decarbonized – in a very efficient way.

Author: Hanno Böck

Brief

-

Green ammonia is considered a future clean shipping fuel, but due to its toxicity, it comes with significant safety risks. The Ammonia Energy Association invited an ammonia safety expert to share some insights, which I covered in an article for Fathom World.

-

Dairy production is a major emitter of greenhouse gases. The company Remilk is producing an animal-free alternative and just gained regulatory approval for its product in Israel.

-

Carbon Capture and Storage (CCS) will likely play a key role in decarbonizing industries with few alternatives. But that will mean expanding carbon dioxide pipelines, which comes with risks. NPR reports about a pipeline rupture of a CO₂ pipeline that happened in 2020 in the village of Satartia in Mississippi, USA.

-

Ardagh has announced plans to build a glass furnace powered by 80% electricity in Obernkirchen, Germany. Existing glass production uses mostly fossil gas. It was planned to build this hybrid furnace as a collaboration project by several companies under the umbrella of the European Container Glass Federation (FEVE). However, that original project failed to get funding from the EU Innovation Fund. The new project, now called NextGen furnace, received financial support from an industry decarbonization program of the German government.